Information for the consumer

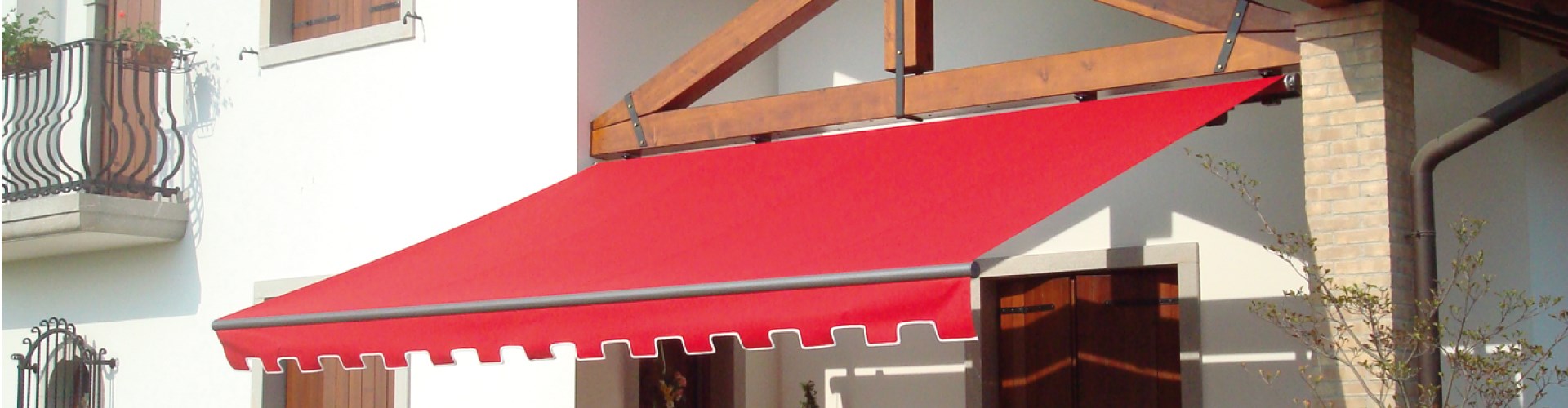

A sun awning is installed with the aim to protect people and environments from solar radiation. In fact, through the regulation of heat and light, it provides greater thermal and visual comfort. Sun awnings, or solar shading systems in general, are installed mainly to save energy or for privacy.

TEMPOTEST® fabrics must therefore meet demanding technical and stylistic requirements and are subjected to strict laboratory tests during the whole production process. These tests will ensure the high performances required, which are then covered by warranty.

QUALITY, LIMITATION AND TECHNICAL POTENTIAL OF ACRYLIC FABRIC FOR SUN PROTECTION

Weight, breaking load, tearing resistance, dimensional variation, water column, water repellency, colour fastness to light and weathering, behaviour towards solar energy and other characteristics, are measured with highly sophisticated precision instruments to comply with specific international standards. Due to the nature of the fibre, once mounted on the structures, fabrics may show small irregularities, sometimes erroneously considered imperfections.

The next pictures show details of some possible fabric effects that may occur. These effects are due to the intrinsic characteristics of the fibre, the fabric and the sun awning itself and should not be considered defects. As part of the technical characteristics of the fibre, these effects are not only present on TEMPOTEST® fabrics, but on all similar fabrics sold in the market. It is possible to limit the intensity of these effects through correct installation. It is correct to insist that none of these aesthetic imperfections that may occur, will compromise the technical usefulness of the fabric. Its performance and suitability in terms of UV protection, energy saving or privacy, are not affected.

UNDULATIONS NEAR THE SEAMS

The continuous action of winding and unwinding the cloth may cause an over tension in the seams area, where the fabrics are overlapped and therefore thicker. This over tension could make undulations in the area near the seam. This phenomenon could be accentuated by humidity and may be more or less evident depending on the fabric colour or in different light conditions. The formation of undulations become more likely with the increase of the awning dimensions, or with the increase of the tension applied to the cloth. These undulations may also be known as “embossing”.

UNDULATIONS IN THE CENTRE OF THE CLOTH OR HONEYCOMB

It is possible that during winding and unwinding, the fabric can suffer some light movement. Over time, this can cause some undulations that may take the shape of honeycomb. The greater the number of fabric layers wrapped on the roll, that is the awning protrusion, the greater is the possibility of a movement of the fabric in the phase of opening and closing, and therefore some of these undulations can form. If the fabric is wound when still wet, these phenomena will be accentuated. Winding the fabric only when it is dry also prevents the formation of an environment suitable for the growth of mould, a phenomenon that can occur when there is organic dirt (pollen, tree resin, smog, etc.) on the awning, which becomes a breeding ground for mould, especially when the environment is hot, humid and poorly ventilated.

UNDULATIONS TO THE EDGES OF THE CLOTH

In a common awning the fabric is kept in tension simply by the winding roll and by the bar protrusion. Consequently it is possible that that there is not a uniform distribution of the tensions generated on the fabric in such a way that they discharge abnormally on the edges themselves. This phenomenon can be amplified when the awning is wound wet after being exposed to rain. We recommend to let the awning fabric dry before winding it again.

COMPRESSION FOLDS DUE TO WINDING

These folds can be formed during the manufacturing or the assembly of very large awnings. In light colours the phenomenon can be amplified and may show on the surface, beside the fold, some darker colour effects that look like dirt. The movement of the fabrics may accentuate this effect in the long term. Many installers and retailers adopt techniques to transport and install larger fabrics that now minimise the possibility of these unsightly effects. However, a fold is still often unavoidable for fabrics made for awnings or structures longer than 6 metres.

LINES AND WRITE AND EFFECT "PLASTER"

Coating products used to guarantee the performance of sun protection fabrics can cause some light-colored stripes. These stripes, also named “writing effect” are formed through the handling of the fabric. This is an effect more visible on colours of medium intensity.

MICROHOLES IN THE BASKET AWNINGS

Acrylic fabric is treated with a particular finishing that, in addition to ensuring the well-known technical features, makes it rigid and flat, characteristics that allow the fabric to remain well stretched during exposure when installed on traditional awnings. However this kind of fabric, when used for the manufacture of basket awnings, can give rise to the formation of micro-holes in correspondence with the folds of fabric that are formed due to continuous mechanical action of opening and closing.

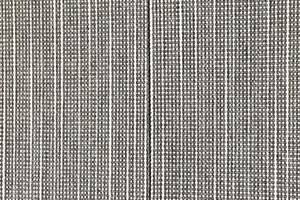

“LIGHT-DARK” EFFECT

TEMPOTEST® research has developed more and more fabrics with special textile structures in which warp and weft threads of increasingly contrasting colours and shades intersect each other to form pleasant optical effects. It is possible that during the making-up of the fabrics, a “light-dark” effect is noted near the seams that join the fabric panels making up the awning. These effects are impossible to eliminate as they are intrinsic to the structure of the fabric, being the result of this new combination of different tones and do not compromise the technical characteristics of the fabric installed on the sun screen.

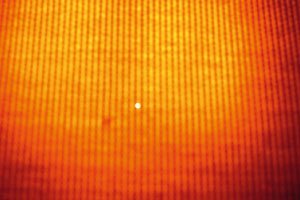

STARS EFFECT

TEMPOTEST® products have a textile structure in which warp and weft yarns intersect to form the fabric: it is perfectly normal that in backlighting there is a passage of light through the points of intersection of the threads. This type of effect does not compromise the technical characteristics of the fabric.