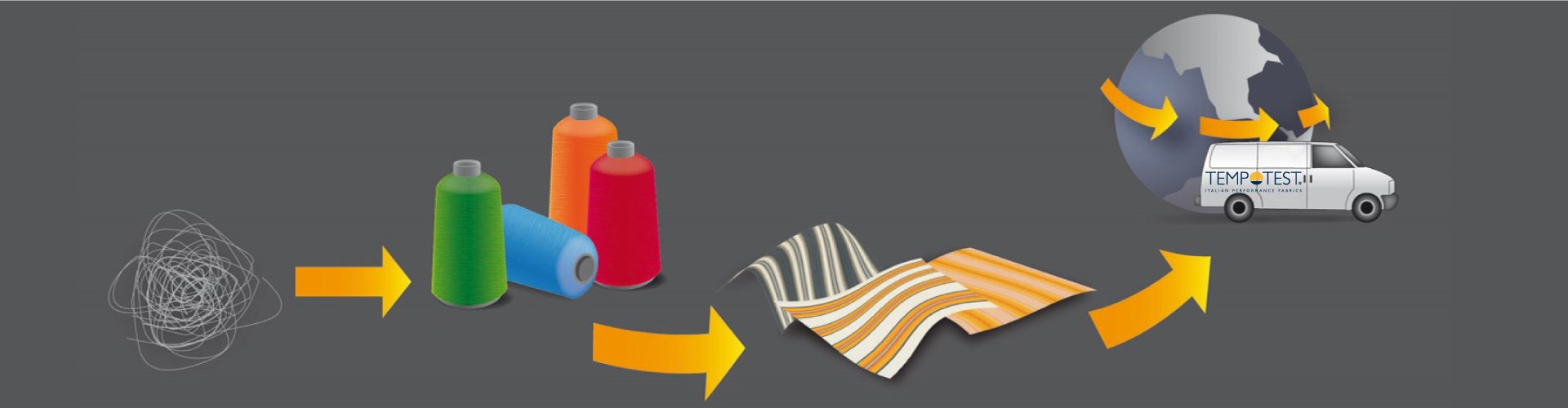

Vertical Production Cycle

|

Parà has over 90 years of experience in the textile industry, and we believe in the quality of our product that is checked and tested from the beginning to the end of the production process. |

|

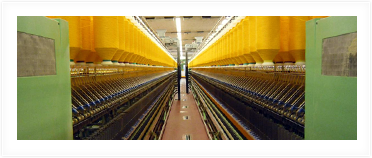

Every day at Parà's production plants are spun over 15.000 kg. of yarn dedicated completely to our weaving plants. |

|

|

Once yarn cones are delivered to the factory in Pontirlo Nuovo (BG) and Vigliano (BI) they find hands of highly experienced employees, who create Parà's complicated design on the warping machines, combining thousand of threads. Afterwards air-jet looms of last technology "made in Europe" pass the weft from one side to the other with a speed that reaches 900 combs per minute. |

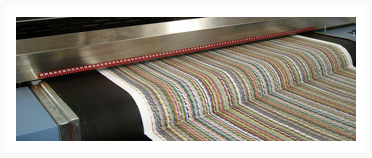

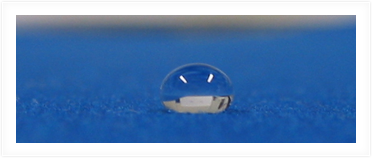

| A 24-colours printing machine, able to work on most kind of fabric is supported today by one of the most modern industrial digital printer in order to guarantee the best production with maximum desired flexibility. To complete the range of outdoor fabrics, Parà has been equipped with a coating machine which is able to give to the fabric special waterproofing features as required by the market. |  |

|

Parà uses textile treatment processes that provide an assurance of quality. All the fabrics produced are subjected to various treatments to give the desired hand, structure and the characteristic technical features. To these finishing treatments follow strict tests carried out both with technological aids and manually since only the sensitivity of the eye and the human hand is able to find further rare imperfections. |